Repair and Maintenance Services

We at Niranjan Engineering works provide an extensive array of specialized services that are customized to fulfill your engineering requirements to keep your equipment operating at peak performance, rely on us for dependable and effective Repair & Maintenance Services offered by us.

Our work incorporates cutting-edge technology and best practices, and we are committed to excellence and innovation. From design and manufacturing to installation and maintenance, we provide a wide range of services to guarantee smooth project execution from beginning to end.

-

Erection & Commissioning of any equipment up to 100 tons.

-

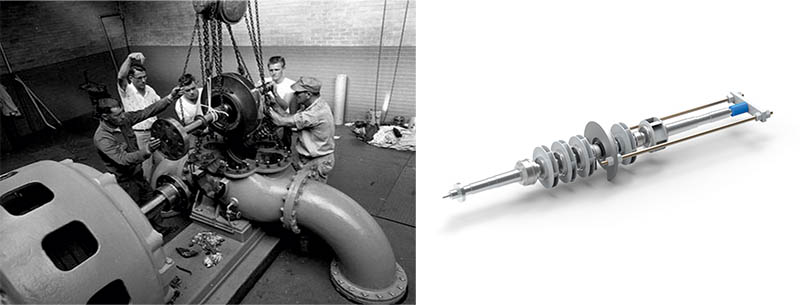

Repair of horizontal and vertical turbine pump.

-

Erection & Commissioning of Diesel Generator Set.

-

In-situ Cylinder Liner Honing Services.

-

Repair of Compressors.

-

Reconditioning of Cylinder Heads.

-

Metal spray jobs. (Thermal Spray)

-

Testing & Calibration of thermal relief valve and Safety Valves.

-

Repair of Gate Valves.

-

Hydro-testing of various Equipments.

Erection & Installation of Engine

in 1982 we have executed erection of mainline pumping unit including engine, gear box, pump on common bedplate, Disconnecting Existing Piping, Electrical, Instrumentation and civil works at Indian Oil Corporation Viramgam & Abu-Road Station.

In-situ Machining

-

In-situ Cylinder Liner Honing

Benefits of Honing and Deglazing

1. It Increases Service Life of Liners, Rings and Pistons

2. Reduces risk of blow-by and seizure Oval Wear in Cylinder liners can be rectified and prevented by regular honing. The Honing also produces an adequate running surface thereby reducing wear-in time of new piston rings.

3. Reduces Lube oil consumption. Restoring good line characteristics makes it possible to control lube oil consumption and save substantial costs.

Repair of Pumps & Rotor Assembly

Metrology Inspection Services

We, Niranjan Engineering works strive hard to better engineering quality products and constantly try to be upgrade with the time. As a part of the process we are offering Metrology Inspection Services to various industries as per following ...

-

Component Measuring Services on CMM (Model: Carl Zeiss-Contura G2) Table Size 700mm x 700mm x 600mm

-

Reverse Engineering & 3D Modeling of part using Siemens SolidEdge ST7 and CCcurve.

-

Surface Roughness Measurement (Make : Mitutoyo Corporation, Japan)

-

Hardness Testing with Portable Hardness Tester (Make : Proceq, Switzerland)

-

Cross Hatch Adhesion Testing (Inspection of Coating Adhesion)

-

Pencil Hardness Testing (Inspection of Coating Hardness)